INTRO

Type

Univesity / Client Project

Year

2016

Client

Philips

Duration

22 weeks

Team

Lorenz Bauer

Priska van Binsbergen

Tine Hoogterp

Renate Hulst

Debbie Rouw

Karthik Mahadevan

About

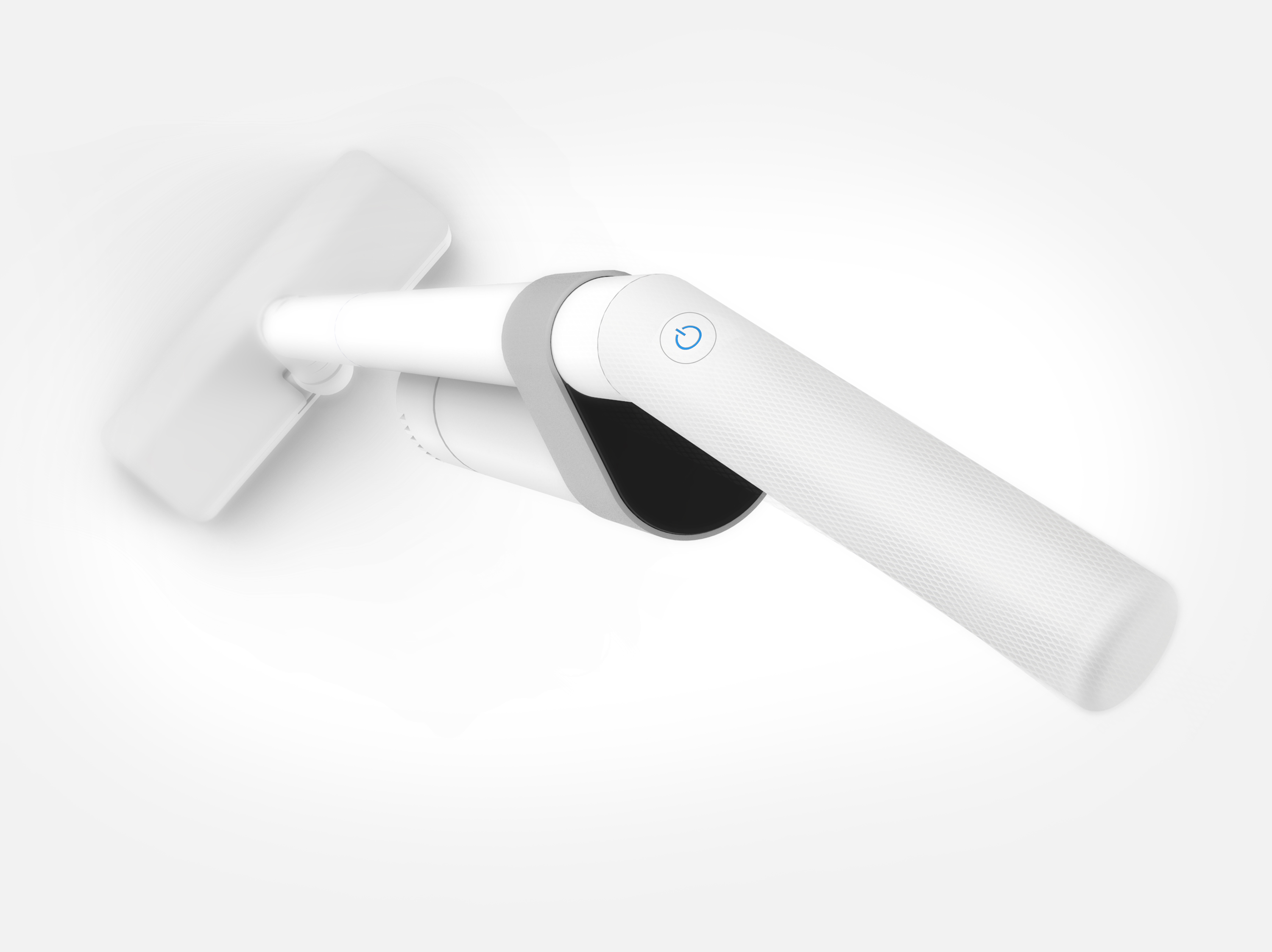

The Philips MinimalPro was designed for Philips in cooperation with TU Delft for the embodiment design course. A team of six students designed a minimalist stick vacuum cleaner and built a working prototype. Due to an ongoing NDA no technical details can be shown.

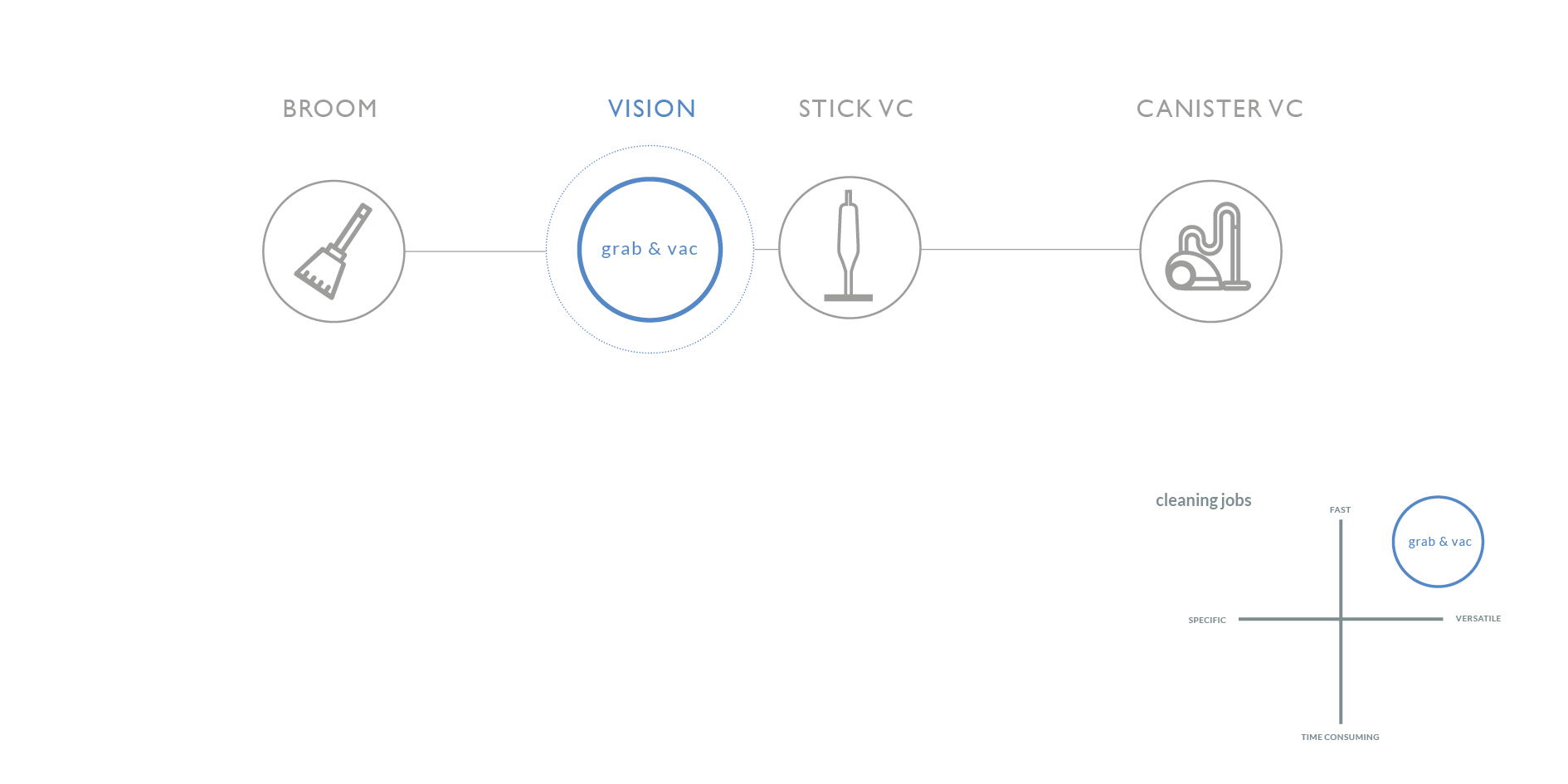

The Philips MinimalPro is a minimalistic stick vacuum cleaner designed for minor cleaning task. The use case of the vacuum cleaner is comparable to situations where normally a broom is taken. For fast accessibility, the product should be aesthetically unobtrusive to blend into the surrounding living environment, instead of being hidden in a closet.

DESIGN PROCESS

ASSIGNMENT

The project‘s assignment asked for the design and developementof a minimalisic stick vacuum cleaner with a dust bag. The battery powerd product should be designed for minor cleaning task - compareable to usecases where normally a traditional broom is taken. The product should be unobtrusive to blend in its surrounding environment for fast accessebility.

MOODBOARD

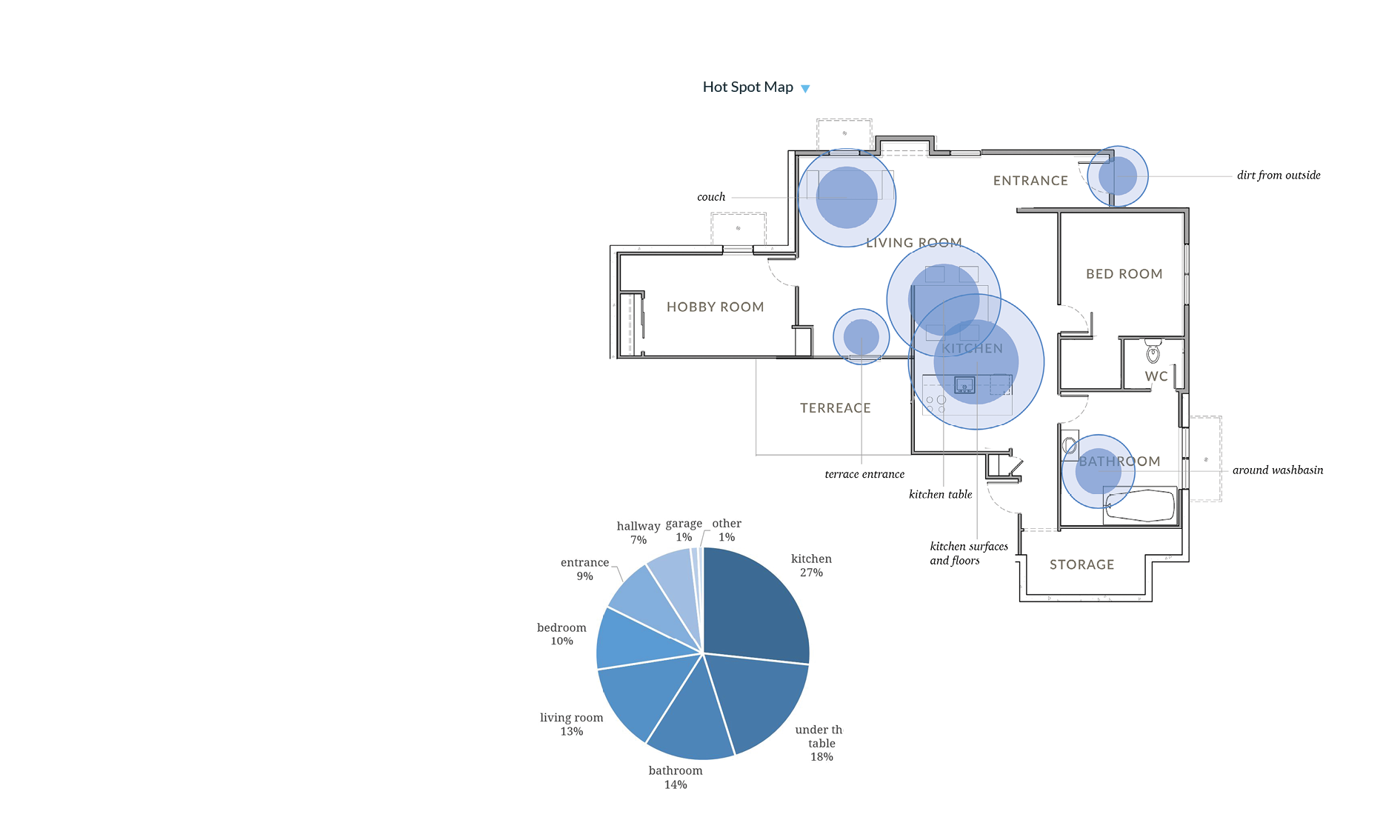

HOT SPOT MAP

An online survey about cleaning habits was conducted among 100 participants to study the. The questions were focussed on getting insight into certain areas and situations in which people have to clean most often. The survey showed that there are special areas in everyone’s home which need to be cleaned more often, the so-called ‘hot spots’. The result stated that parents with children and/or owners of pets have the strongest need for quick cleaning jobs and the most frequent hot spots can be found in the kitchen and under the dining table.

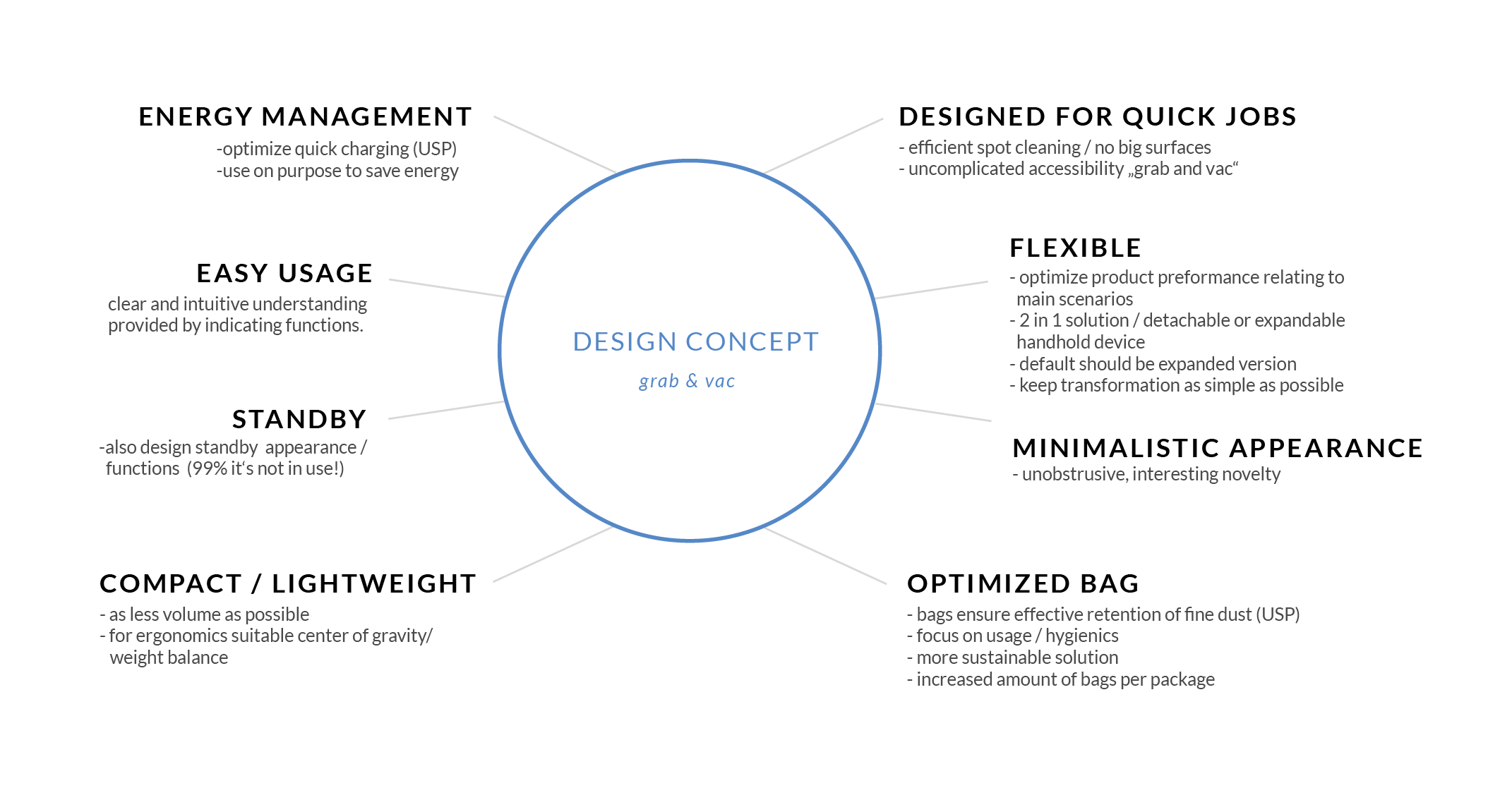

DESIGN OUTLINE

The assignment and crucial first insights were translated into a design outline to generate and guideline. Some of these goals are elaborated a little bit more than others during the design process. However, every aspect was kept in mind when decisions have been made.

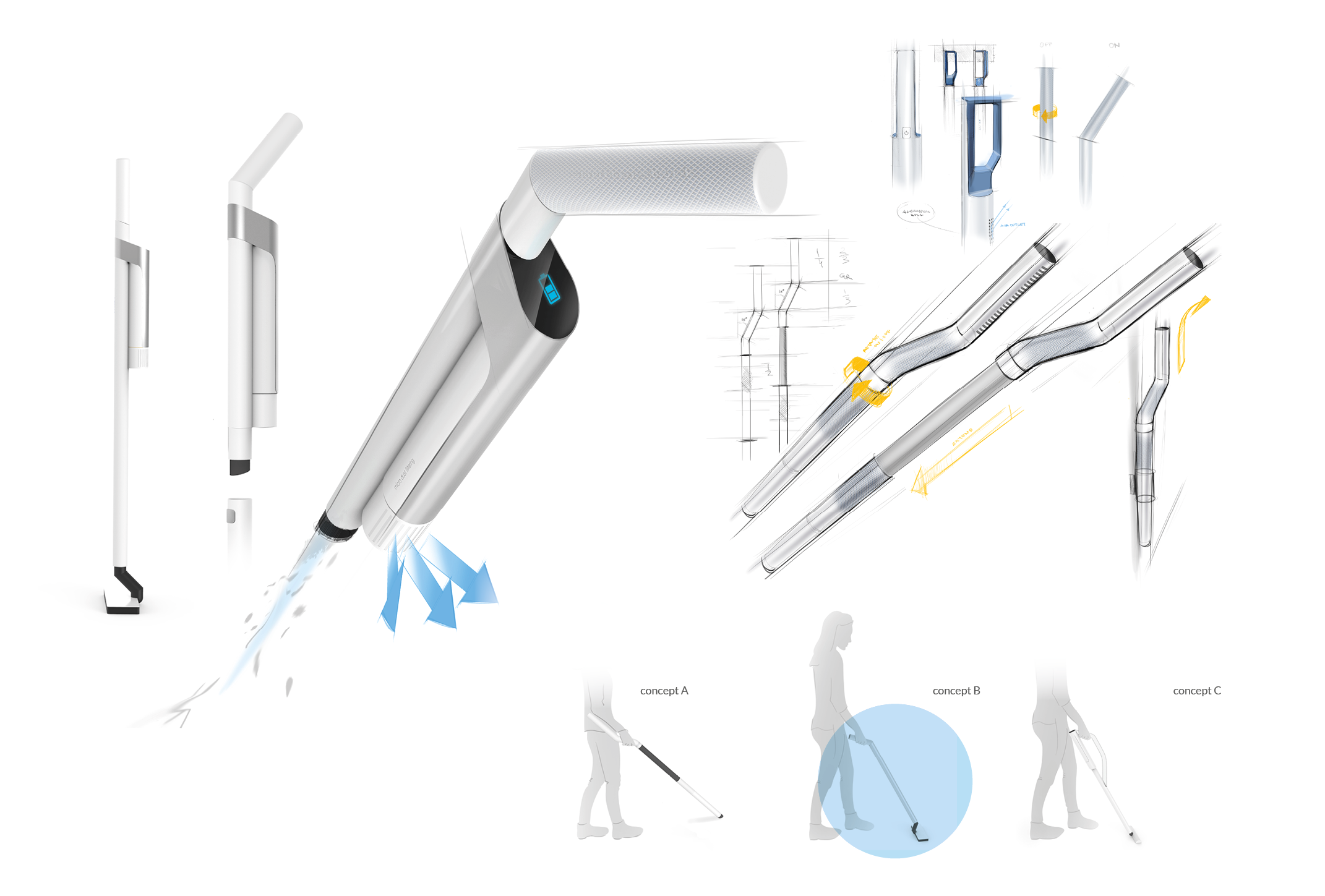

IDEATION

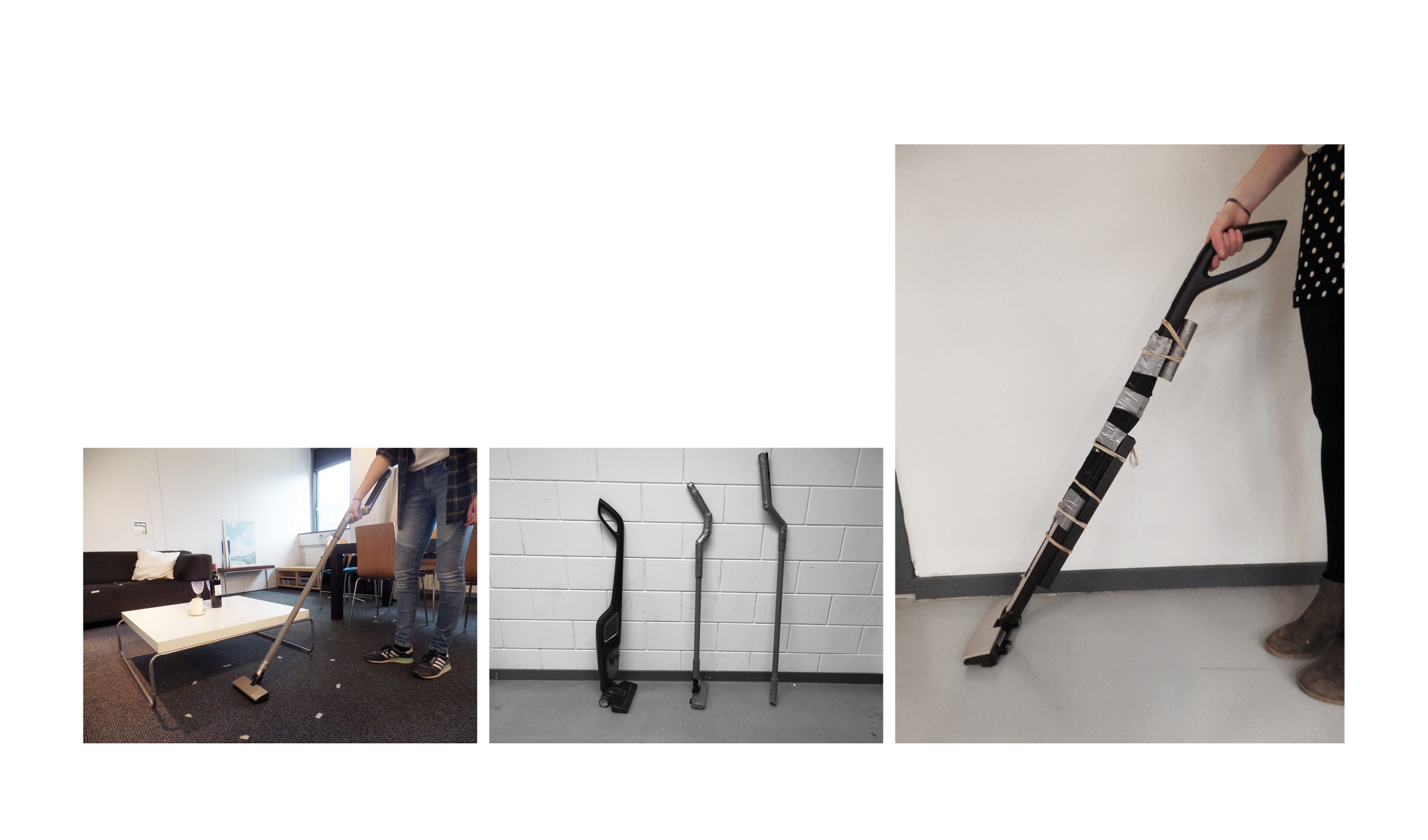

MOCKUPS / TESTING

Once several concept Ideas were sketched on paper the team started to experimenting and testing 'quick and dirty' mockups. As a benchmark, the team disassembled several similar products to learn from and take several parts for testing. Next to getting a better understanding of volume and proportions, also weight was attached to explore weight distribution. Some of the mockups then were tested with participants in a realistic setup to evaluate on ergonomics and usability.

FINAL DESIGN

USAGE SCENARIO

activate

detach handheld unit

usage

handheld

DESIGN DETAILS

The challenge was to design a clean and minimalistic look, combined with no restrictions concerning movability. An eye-catching and functional feature of the concept is the aluminum bracket which embraces the bag cylinder and the status display. By sliding the extruded aluminum bracket upwards, the bag cylinder can be detached to replace the dust bag directly above the trash can.

All steering movements are provided by the nozzle’s joint. Due to its bend, the weight of the main body is centered over the nozzle. The integrative joint only needs a single cut and a hidden hinge to achieve full range moveability. The cut is highlighted by a blue ring to indicate activity.

TECHNICAL DETAILS

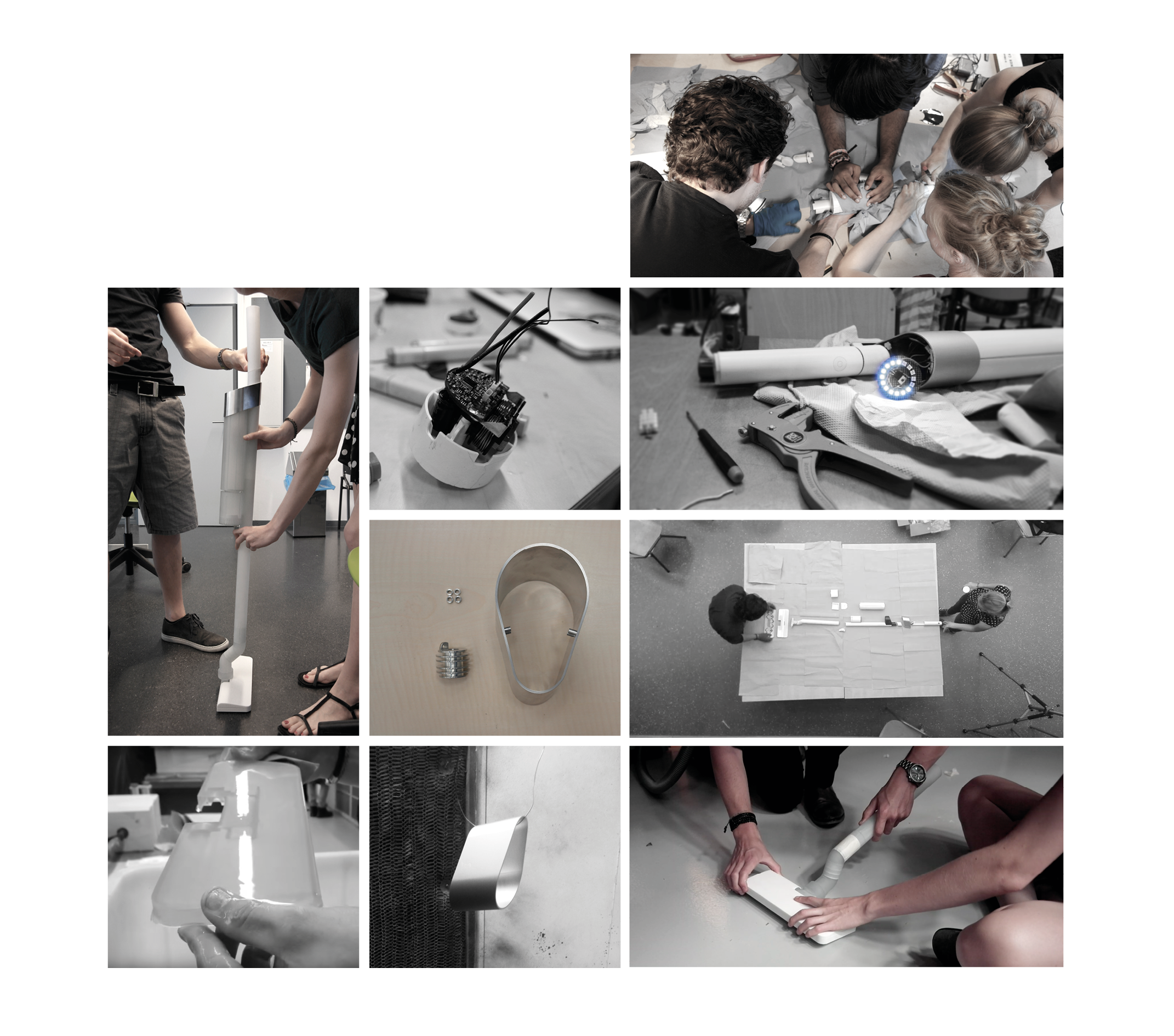

FUNCTIONAL PROTOTYPE

After the embodiment phase, a working prototype was built. The parts were designed in SolidWorks and tested with low-resolution FDM prints. After many iterations, the final parts were 3D printed in SLA technology and spray painted. The compact motor and fan unit was taken from a Dyson V6 and implemented into the prototype. It is powered by 6 Lithium-Ion cells which are stored in the handle to ensure an ergonomically pleasing center of gravity. The status display consists out of a LED ring and was programmed via Arduino to read and display the current battery status. The aluminum bracket was milled out from aluminum and anodized for a semi-matte finish.

PROTOTYPE

work

IOT Product LanguageOnePlus (2021)

Gaggenau Motion PortGaggenau / BSH (2018)

Omni ProAxion (2022)

Gravity OneKEF / Porsche Design (2016)

Over Ear HeadphonesPorsche Design / KEF (2016)

Minimal ProPHILIPS (2016)

Gaggenau Home GardenGaggenau